Blog

Tutorials

Choosing a Database for Inventory Management System

Discover the best database for inventory management system options. Compare SQL vs NoSQL, explore schema design, and find the right fit for your business.

Nafis Amiri

Co-Founder of CatDoes

Jan 14, 2026

Picking the right database for your inventory management system isn't just a technical detail. It's one of the most important decisions you'll make for the health of your business. This database is the central brain of your operation, the single source of truth that tracks every single item, sale, and restock.

Get it right, and you prevent costly mistakes like stockouts or overstocking that directly hit your bottom line and frustrate customers.

Why Your Database Choice Is So Critical

Think of it this way: your database is the command center that makes sure what you see on your screen perfectly matches what’s sitting on your shelves. Without this solid foundation, you’re basically just guessing about your stock levels, and that's a fast path to chaos.

A well-designed system ensures that when an item sells online, its stock count updates instantly everywhere else. This is what stops that dreaded "overselling" scenario where a customer buys something you no longer have. It’s the difference between a smooth, professional operation and one that’s constantly putting out fires.

For a deeper dive on why this is so much better than a simple spreadsheet, check out our guide on the fundamental differences between spreadsheets vs databases.

A reliable inventory database is more than just a tracking tool; it’s a strategic asset. It gives you the hard data you need for accurate forecasting, efficient supply chain management, and smart business decisions that fuel real growth.

The Foundation for Growth

The need for solid inventory management is only getting more intense. The global market for this software is projected to hit USD 2,874.65 million by 2026, growing at a steady clip of 10.8% a year. This explosion in growth shows just how crucial a well-chosen database is for handling today’s complex supply chains, as highlighted in this comprehensive market analysis.

This guide will demystify the entire process. We'll walk through the key database types and show you how modern tools have made building a powerful system accessible to everyone. With platforms like Supabase and CatDoes, creating a high-performance inventory app is no longer something reserved for giant corporations with massive tech teams.

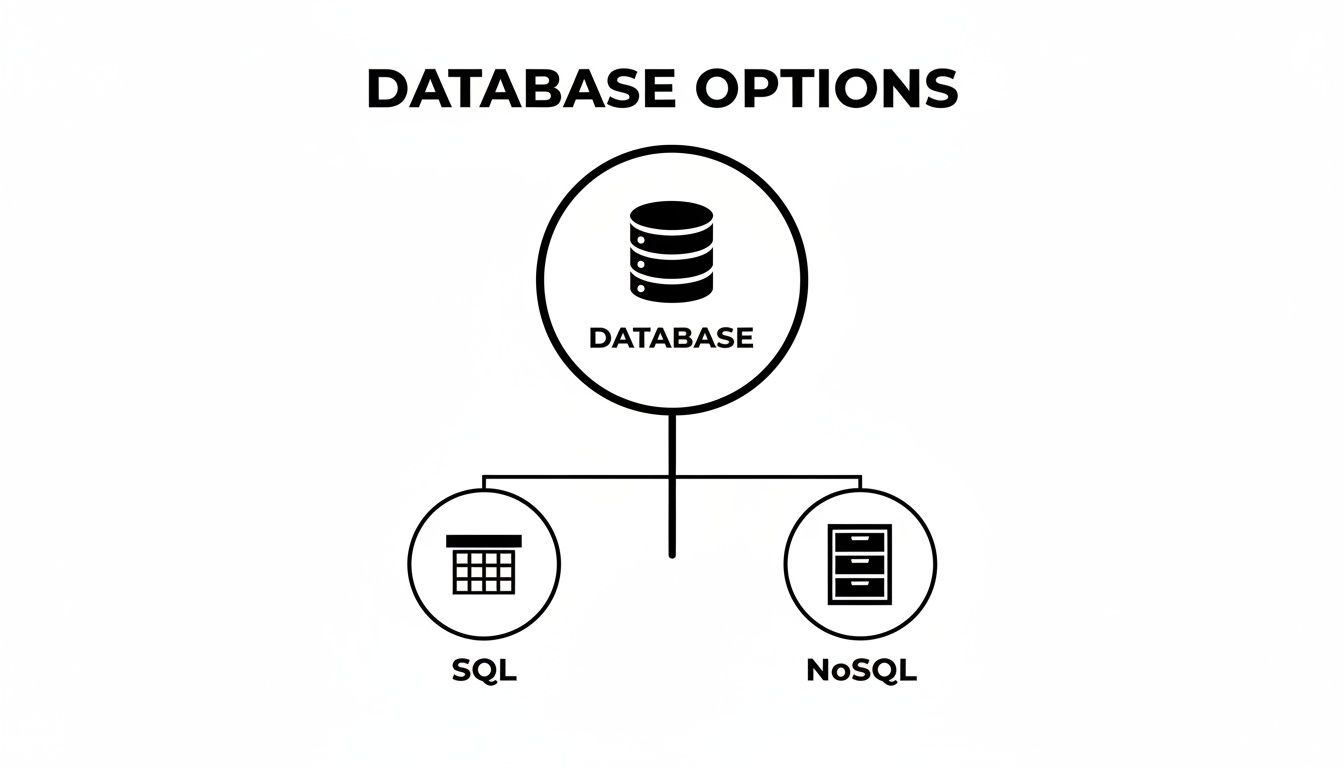

SQL vs. NoSQL: Choosing the Right Database for Your Inventory

When you start digging into databases for an inventory system, you’ll run into two big families: SQL and NoSQL. Think of them as two different ways of organizing a warehouse. One is a perfectly gridded system with numbered aisles and shelves for specific items. The other is more like a collection of customizable storage bins, where you can toss in items of all different shapes and sizes.

This isn’t just a technical detail; it’s a foundational choice that dictates how your inventory data is stored, accessed, and protected. The right decision hinges entirely on what your business needs. How complex are your products? How much do you expect to grow? And, most importantly, how critical is it that your stock counts are 100% accurate, every single second of the day?

The Structured World of SQL Databases

For decades, relational databases, the ones that speak Structured Query Language (SQL), have been the bedrock of business applications, and for good reason. They organize data into neat tables with predefined rows and columns, a bit like a collection of interconnected spreadsheets. This structure is a perfect match for inventory management because the relationships between your products, suppliers, and orders are usually clear and consistent.

For instance, you'll have separate tables for:

Products (SKU, name, price, description)

Suppliers (name, contact info, address)

Orders (order ID, customer, date, status)

These tables are linked together using keys, creating a logical and predictable map of your entire operation. This rigid framework enforces data integrity, which is just a fancy way of saying it prevents mistakes, like an order being placed for a product that doesn't exist. For an inventory system, where a single error can lead to overselling or stockouts, that kind of reliability is gold.

PostgreSQL is a powerhouse in the SQL world. It's an open-source database known for being incredibly robust and feature-rich. It's the engine behind modern platforms like Supabase, which makes building sophisticated applications much faster. Our article on what Supabase is is a great starting point if you want to see how it leverages Postgres for today's apps.

The Flexible Approach of NoSQL Databases

On the other side, you have NoSQL databases. The name is a little misleading; it really means "Not Only SQL." These databases were born out of the need to handle massive amounts of unstructured data with incredible speed and flexibility. Instead of tables, they use formats like JSON documents, key-value pairs, or graphs.

Imagine you sell products with a huge range of attributes. A t-shirt just needs size and color. But a custom-built computer needs CPU, RAM, storage type, graphics card, and a dozen other specs. A NoSQL database like MongoDB can handle that chaos easily, storing each unique product in a single "document" without needing a rigid table structure upfront. This makes them fantastic for businesses with rapidly changing product catalogs or those needing to scale out across many servers to handle huge traffic spikes.

But that flexibility comes with a trade-off. Enforcing the strict relationships and transactional consistency that inventory systems demand is often much more complex in a NoSQL world than it is with SQL.

SQL vs NoSQL Databases for Inventory Management

So, which is the right tool for the job? Here’s a quick table to help you compare the two philosophies when it comes to managing inventory.

Feature | Relational (SQL) Databases | NoSQL Databases |

|---|---|---|

Data Model | Structured tables with predefined schemas. | Flexible documents, key-value pairs, or graphs. |

Best For | Systems with clear, predictable relationships like inventory, finance, and e-commerce. | Applications with diverse data types, massive scale, or rapidly evolving requirements. |

Consistency | Strong and guaranteed (ACID compliance), which is vital for transactional accuracy. | Eventual consistency is more common, which may not be ideal for real-time stock counts. |

Scalability | Traditionally scales vertically (more powerful server), but modern systems scale horizontally too. | Excels at horizontal scaling (distributing load across many servers). |

While NoSQL databases have their place, for most inventory management systems, the structured, reliable nature of an SQL database is the smarter, safer choice. The predictable connections between products, stock levels, suppliers, and sales orders are exactly what the relational model was built for.

Ultimately, your database for an inventory management system has to be your source of truth. The powerful consistency guarantees you get from SQL databases like PostgreSQL make them the most dependable foundation you can build on. They ensure every single item is tracked with precision, from the moment it arrives at your warehouse to the second it ships out the door.

Designing Your Inventory Database Schema

Alright, let's move from big ideas to the actual blueprint of your inventory data. This blueprint is called a database schema. Think of it as the architectural drawing for your digital warehouse. It spells out exactly where every piece of information lives and how it connects to everything else.

A well-planned schema is the difference between a system that just works and one that’s a constant source of headaches. It’s what stops you from selling an item you don't have or losing a supplier's contact info. Our goal here is to make schema design feel less like a chore and more like a logical puzzle, giving you a solid model you can tweak for your own app.

The image below shows the two main roads you can go down when picking a database, and this choice directly shapes how you'll build your schema.

This fork in the road, structured SQL tables versus flexible NoSQL documents, is the first major decision that will guide your entire design.

Core Tables for Your Inventory Schema

If you're using a relational database like PostgreSQL (which powers Supabase), your schema is built around interconnected tables. Even in a NoSQL world, you'd think about these as distinct "collections." At a minimum, every inventory system needs these core tables.

Products Table: The heart of the system. This holds every detail about the items you stock and sell.

Suppliers Table: This is your address book for everyone you buy from, tracking all their information.

Warehouses Table: If you have stock in more than one place, this table is non-negotiable for knowing where it all is.

Orders Table: This tracks every customer purchase and every order you place with your suppliers.

These four pillars form the foundation of a solid database for an inventory management system, making sure your most important business data is organized, easy to find, and trustworthy.

Detailing the Essential Fields

Now, let's zoom in and figure out what information, or fields, goes into each table. Think of a field as a labeled column in a spreadsheet; it holds one specific piece of data for every single record.

A good schema captures everything you need without creating clutter or duplicating information.

The secret to a great schema is to think about the real-world relationships between your data. A product comes from a supplier, is stored in a warehouse, and is sold through an order. Your database must reflect these connections logically.

Here’s a practical look at the fields you’d want in your most important tables:

1. Products Table This is your master catalog. Each row is a unique item you carry.

product_id(Primary Key): A unique number that identifies each product.sku: The Stock Keeping Unit, your internal code for tracking.name: The public-facing name of the product.description: More details for your listings or internal notes.cost_price: What you pay to get the item.selling_price: What the customer pays for the item.supplier_id(Foreign Key): This links the product to its record in theSupplierstable, creating that crucial connection.

2. Inventory Stock Table This table is all about the numbers: how much of each product you have and where. We often separate this from the main product table because it makes managing inventory across multiple locations much cleaner.

inventory_id(Primary Key): A unique ID for this specific stock record.product_id(Foreign Key): Links back to the specific item in theProductstable.warehouse_id(Foreign Key): Points to the location in theWarehousestable.quantity_on_hand: The actual, current count of units at that location.reorder_level: The stock number that tells your system it’s time to order more.

When you structure your data this way, you’re building a powerful and scalable foundation. When a sale happens, your app can instantly find the product, check its stock in the nearest warehouse, and update the quantity, all by following the links between these tables. This simple, logical structure is the key to an inventory system you can actually rely on.

Building a High-Performing Inventory Database

A well-designed schema gives your inventory database a solid skeleton. But to turn that skeleton into a high-performance athlete, you need the muscles and reflexes that make it fast, reliable, and trustworthy. These are the features that transform a simple data store into a robust database for an inventory management system that can handle the pressures of the real world.

Think of it this way: a blueprint for a car is essential, but it’s the engine, transmission, and brakes that determine how it actually performs. For your database, these critical components are things like indexing for speed, transactions for reliability, and concurrency control for managing multiple users at once.

Speeding Up Searches with Indexing

Imagine trying to find a specific topic in a massive textbook that has no index. You’d have to flip through every single page, a slow and painful process. A database index works the exact same way for your data.

Without an index, searching for a product by its SKU forces the database to scan every single row in your Products table until it finds a match. But with an index on the SKU column, the database can instantly jump to the correct location, pulling the data in a fraction of the time.

This isn't just a convenience; it's critical for a good user experience. Key columns to index in any inventory system include:

Product IDs and SKUs: For lightning-fast product lookups.

Order IDs: To find specific customer or supplier orders instantly.

Customer or Supplier Names: For quick searches in your contact tables.

Creating an index is a fundamental first step in building a responsive inventory app. It ensures your staff and customers get the information they need without the wait.

Ensuring Data Integrity with Transactions

In an inventory system, many actions are actually a sequence of steps that must all succeed or fail together. When a customer buys a product, for instance, at least two things need to happen: the quantity on hand must decrease, and a new sales order must be created.

But what if the system deducts the stock, then crashes before it saves the order? You’d end up with a "ghost" deduction in your inventory, leading to confusion and inaccurate stock levels. This is where database transactions save the day.

A transaction is an all-or-nothing operation. It bundles multiple database commands into a single unit of work that either completes entirely or fails completely, leaving the database in its original state.

This core principle, known as atomicity, guarantees your data stays consistent and reliable. It prevents the kind of partial updates that corrupt your records, ensuring a sale is only final if both the inventory update and order creation are successful. It’s what builds trust in your system's data.

Managing Simultaneous Updates with Concurrency Control

Your inventory system will almost certainly be used by multiple people or automated processes at the same time. A warehouse manager might be updating stock levels while a sales rep places an order for the same item, all while your e-commerce site processes an online sale.

This is where concurrency control becomes essential. It’s the database’s traffic management system, preventing these simultaneous actions from tripping over each other and causing data conflicts. For example, it stops two users from selling the very last item in stock at the exact same moment, a scenario that would lead to overselling and unhappy customers.

The demand for these robust database features is growing. The inventory management software market is forecasted to hit USD 2.75 billion globally by the end of 2026, with North America leading at a 35.01% share due to the high demand for efficient supply chains. This growth is driven by the adoption of technologies like barcode and RFID integration, which rely on high-performance databases to sync data in real time. For developers using platforms like CatDoes to create React Native apps with Supabase backends, this highlights a major opportunity to build systems that meet modern market expectations.

Ultimately, these advanced features work together to create a database you can depend on. To go deeper on optimizing your inventory database's speed and efficiency, exploring articles on database performance tuning can provide valuable insights. By implementing indexing, transactions, and concurrency control, you ensure your inventory system is not just functional but also fast, accurate, and ready to scale.

Bringing Your Inventory System to Life

It’s one thing to understand the theory behind a good inventory database. It's another thing entirely to turn that knowledge into a working system that actually runs your business. The good news is, you no longer need to write mountains of code to get there. Modern tools bridge the gap between idea and reality, letting anyone from a small shop owner to a startup founder build a powerful app. This is exactly where a platform like CatDoes comes in.

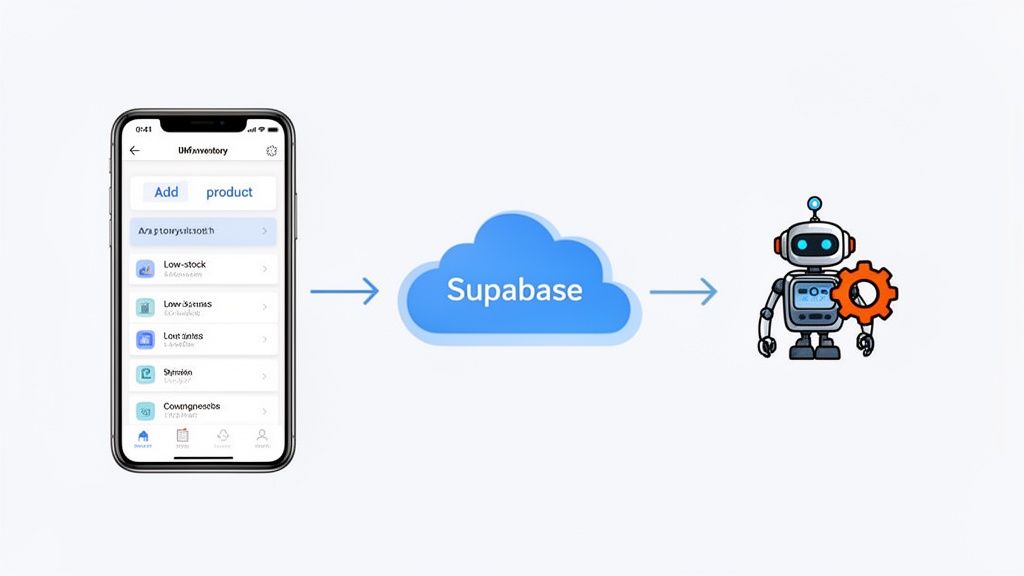

Imagine just describing what you need in plain English and watching a mobile app spring to life. That’s the core idea. Specialized AI agents take your requests and translate them into a functional mobile application, complete with the backend to power it.

This completely lowers the barrier to entry. Instead of getting tangled up in technical details, you can focus on the business logic: how you need your inventory to work. The heavy lifting of creating the user interface and connecting it to a reliable database for your inventory management system is handled for you.

From Idea to App: A Practical Example

Let's walk through how this works in the real world. Picture the owner of a small boutique shop. They need a simple app to track what’s in stock, add new products, and get an alert when items are running low.

With a tool like CatDoes, the whole process is conversational. The owner simply states their needs:

"I need a screen to add a new product." The AI agents create an interface with fields for a product name, SKU, price, and initial quantity.

"Show me a list of all my products." This request generates a screen displaying all items, probably with their current stock counts.

"I need a way to see low-stock items." The system builds a view that filters and displays products that have dropped below a set reorder point.

Behind the scenes, the platform isn't just building the mobile app. It’s also creating the backend logic and database schema required to make these features work, automatically generating the necessary tables for products and inventory levels.

Integrating a Powerful Supabase Backend

While the platform can create the backend for you, it also gives you the option to integrate with Supabase. This move gives you the power of an enterprise-grade PostgreSQL database without the usual setup headaches. By connecting Supabase, your app instantly gets a robust, scalable, and secure foundation for its data.

This integration is a game-changer. You can start with a simple, AI-generated app and seamlessly grow into a system that handles thousands of products and transactions, all built on trusted, open-source tech like Postgres.

This approach is perfectly in step with where the industry is heading. Cloud-based databases have become the standard, capturing 62% of the market and projected to grow at a 14.2% CAGR through 2030. Businesses are moving to the cloud for faster scaling and better cost efficiency, and you can read more on these inventory management market trends to see why. For CatDoes users, integrating with Supabase means your app is built on a production-ready backend that’s already part of this cloud-first world, supporting everything from authentication to real-time updates.

This whole setup makes powerful technology accessible, letting non-engineers launch inventory apps that can scale globally. If you're looking to build from the ground up, our guide on choosing a database for a small business offers more insight into making the right architectural calls. With the right tools, moving from a simple idea to a fully working inventory system is faster than ever before.

Final Thoughts on Building Your System

We've covered a lot of ground, but it all comes down to this: choosing the right database for an inventory management system is the single most important decision you'll make. It’s the foundation for everything that follows. We've looked at the trade-offs between SQL and NoSQL and seen why a thoughtful schema is non-negotiable for keeping your data clean and reliable.

The good news? The journey from a great idea to a working system is shorter than ever.

The real takeaway here is a sense of empowerment. With modern tools like CatDoes and Supabase, you don't need a massive technical team to build a powerful inventory application. These platforms have leveled the playing field, putting control back into your hands.

Entrepreneurs and business owners can now leverage powerful automation to gain precise control over their stock, reduce operational costs, and ultimately improve customer satisfaction.

Turning Knowledge into Action

Your next step is to put these ideas to work. Think of the database design principles we discussed as your blueprint. This blueprint will help you build a system that grows with your business, saving you from the classic headaches of overselling popular items or running out of stock unexpectedly. A well-designed database doesn't just hold information; it gives you the clear, trustworthy insights needed for smart forecasting and better decisions.

For more perspectives and practical advice on inventory management databases, consider checking Timbercloud's blog for additional insights.

Ultimately, the goal is to build a single source of truth for your entire operation. By starting with a strong database foundation, you create a resilient system that not only supports your business today but is ready for whatever comes next. You have the knowledge. Now you can start building with confidence.

Frequently Asked Questions

Getting into the weeds of database choices for an inventory system can bring up a lot of questions. Here are some straightforward answers to the common ones, designed to help you make a solid decision for your business.

Which Database Is Best for A Small Business Inventory System?

For most small businesses, you can't go wrong with a relational SQL database like PostgreSQL. It’s the powerhouse engine behind platforms like Supabase, and for good reason. Its structured nature is perfect for handling the clean, predictable relationships between things like products, suppliers, and customer orders.

This structure is what guarantees data consistency, something absolutely critical when you need to know exactly how many units you have in stock. Plus, modern cloud SQL databases have more than enough power to scale with you as you grow. Best of all, tools like CatDoes working with Supabase make setting up a serious, reliable database incredibly easy, even if you don't have a technical expert on hand.

Can I Use Excel as a Database for My Inventory?

Look, we've all been there. Many businesses start tracking inventory in Excel, but it’s a temporary solution that creates massive headaches as soon as you start to grow. Excel simply wasn't built for the job.

Spreadsheets are missing the critical features you need for managing multiple users at once, ensuring your data is always accurate, and running complex reports. This almost always leads to manual data entry mistakes, expensive stock errors, and hours of wasted time.

Making the jump to a real database for an inventory management system will save you countless frustrations, slash costly errors, and give your entire operation a foundation you can actually trust.

How Does a Database Enable Real-time Inventory Tracking?

A modern database, connected to your inventory app, is the secret to real-time tracking. It acts as the single source of truth that gets updated instantly with every single stock movement. The whole process is seamless and incredibly powerful.

Here’s a simple breakdown of how it works:

A Sale Happens: A customer buys something from your online store or physical shop.

Instant Update: The point-of-sale or e-commerce system immediately tells the database what happened.

Stock Is Adjusted: A database transaction instantly reduces the stock count for that specific product.

Everyone Sees It: This new, lower stock level is immediately reflected everywhere, from your warehouse dashboard to the product page your next customer sees.

This instant update is what stops you from accidentally selling an item you don't have. It gives you a precise, up-to-the-second picture of your entire inventory, letting you make smarter buying decisions and keeping customers happy. It turns inventory management from a painful, reactive chore into a proactive business advantage.

Ready to build your own inventory management app without getting tangled in the technical details? With CatDoes, you can describe your idea in plain language and watch as AI agents build a production-ready mobile app and backend for you. Start building for free on catdoes.com and turn your concept into reality today.

Nafis Amiri

Co-Founder of CatDoes